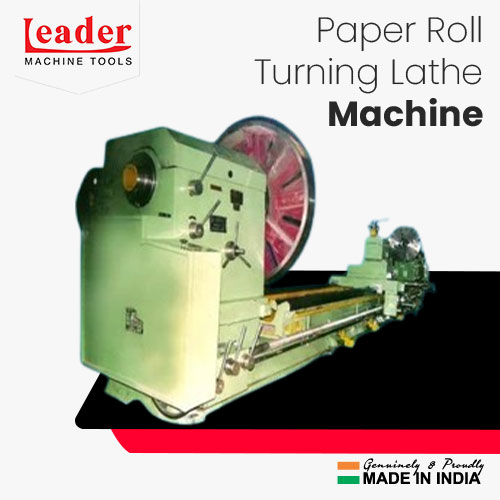

Paper Roll Turning Lathe Machine

Paper Roll Turning Lathe Machine Manufacturer in Raigad

Leader Machine Tools is a trusted Paper Roll Turning Lathe Machine Manufacturer in Raigad, delivering high-performance and precision-engineered solutions for the paper and packaging industry. Our paper roll turning lathe machine in Raigad are designed to enhance efficiency, durability, and accuracy in roll processing. With advanced features and robust construction, our turning lathe machine in Raigad ensure seamless operation and long-term reliability. We prioritize quality, innovation, and customer satisfaction, making us the preferred choice for businesses seeking cost-effective and technologically advanced paper roll turning solutions. Choose Leader Machine Tools for superior performance and industry-leading expertise.

Leader Machine Tools is a trusted Paper Roll Turning Lathe Machine Manufacturer in Raigad, delivering high-performance and precision-engineered solutions for the paper and packaging industry. Our paper roll turning lathe machine in Raigad are designed to enhance efficiency, durability, and accuracy in roll processing. With advanced features and robust construction, our turning lathe machine in Raigad ensure seamless operation and long-term reliability. We prioritize quality, innovation, and customer satisfaction, making us the preferred choice for businesses seeking cost-effective and technologically advanced paper roll turning solutions. Choose Leader Machine Tools for superior performance and industry-leading expertise.

Technical Specifications

| BELT DRIVE LATHE MACHINE – 16 FEET MODELS (PEDESTAL + TAPER PLANER) | |||

| Section | Parameter | Pedestal Type (16 FT) | Taper Planer Type (16 FT) |

| BED | Length of Bed | 16 FT | 16 FT |

| Width of Bed | 18" / 400 mm | 26" / 650 mm | |

| CAPACITY | Admit Between Centers | 136" / 3400 mm | 132" / 3350 mm |

| Swing Over Bed | 27" / 700 mm | 36" / 900 mm | |

| Swing Over Cross Slide | 21" / 525 mm | 26" / 650 mm | |

| Swing in Gap | 40" / 1000 mm | 48" / 1200 mm | |

| SPINDLE | Spindle Bore | 2" – 3" | 3" – 12" |

| Spindle Bore (mm) | 50 – 175 mm | 100 – 300 mm | |

| Spindle Speeds | 6 | 6 | |

| THREADING | Lead Screw Pitch | 2 TPI | 2 TPI |

| BSW Thread | 30 (8–28) | 31 (2–24) | |

| Metric Thread | 18 (1–7) | 31 (2–14) | |

| TAILSTOCK | Height of Center | 16" / 400 mm | 18" / 450 mm |

| Tailstock Quill Taper | MT-4 | MT-5 | |

| MOTOR REQUIRED | — | 5 HP | 7.5 HP |

| STANDARD ACCESSORIES | Steady Rest & Follower Rest | ||

| OPTIONAL ACCESSORIES |

4-Jaw Dog Chuck / 3-Jaw Self Centering Chuck / Taper Turning Attachment / Keyway Cutting Attachment / Tool Post Grinding Attachment / Main Motor / Electric Lamp / Quick Change Tool Holder |

||

Features of Paper Roll Turning Lathe Machine

Heavy-Duty Construction

Built with a robust steel frame, our lathe machines ensure stability and longevity. The high-strength body minimizes vibrations, allowing smooth and precise turning of paper rolls.

Heavy-Duty Construction

Built with a robust steel frame, our lathe machines ensure stability and longevity. The high-strength body minimizes vibrations, allowing smooth and precise turning of paper rolls. High-Precision Machining

Equipped with advanced spindle systems and cutting tools, the machine delivers high accuracy in shaping and resizing paper rolls. It ensures smooth surface finishing with minimal material waste.

High-Precision Machining

Equipped with advanced spindle systems and cutting tools, the machine delivers high accuracy in shaping and resizing paper rolls. It ensures smooth surface finishing with minimal material waste. User-Friendly Controls

Featuring an intuitive control panel, our machine offers easy operation with adjustable speed settings, automatic feed control, and customizable cutting depths for different paper roll sizes.

User-Friendly Controls

Featuring an intuitive control panel, our machine offers easy operation with adjustable speed settings, automatic feed control, and customizable cutting depths for different paper roll sizes. Energy-Efficient Performance

Our lathe machines are engineered with low power consumption motors, reducing energy costs while maintaining optimal productivity. The efficient cooling system prevents overheating during continuous operations.

Energy-Efficient Performance

Our lathe machines are engineered with low power consumption motors, reducing energy costs while maintaining optimal productivity. The efficient cooling system prevents overheating during continuous operations. Customizable Design

We offer customization options to meet specific client requirements, including variable spindle speeds, different bed lengths, and automatic lubrication systems for enhanced performance and longevity.

Customizable Design

We offer customization options to meet specific client requirements, including variable spindle speeds, different bed lengths, and automatic lubrication systems for enhanced performance and longevity.

Applications of Paper Roll Turning Lathe Machine

Our Paper Roll Turning Lathe Machine is widely used across various industries that require precise cutting, shaping, and finishing of paper rolls. Some key applications include:

Sticker Production

Assists in producing accurately sized rolls for printing high-quality labels.

Tissue Paper

Used for cutting and finishing tissue paper rolls efficiently.

Printing Industry

Ensures proper sizing and finishing of paper rolls for seamless printing processes.

Paper Mills

For reshaping and resizing jumbo paper rolls with precision.

Packaging Industry

Helps in converting raw paper rolls into packaging material for different applications.

Why Choose Leaders Machine Tools?

Leader Machine Tools is a leading name in precision-engineered lathe machines, offering unmatched quality and service. Here’s why businesses prefer us:

-

Industry Expertise

Industry ExpertiseWith years of experience, we understand industry challenges and provide tailored solutions to meet specific customer needs.

-

Uncompromised Quality

Uncompromised QualityWe use top-grade materials and advanced technology to manufacture durable and high-performance machines.

-

Innovative Designs

Innovative DesignsOur machines come with cutting-edge features like automated controls, energy efficiency, and customizable options for enhanced functionality.

-

Competitive Pricing

Competitive PricingWe offer the best value for money, delivering high-quality machines at cost-effective prices without compromising on performance.

FAQs – Paper Roll Turning Lathe Machine

It is designed specifically for machining, finishing, and profiling large paper rolls, rubber rolls, and industrial cylindrical components with high precision.

Yes, we manufacture machines in multiple lengths, diameters, and spindle bores to match your exact roll size and production needs.

Absolutely. Our paper roll lathes are built with heavy cast iron structures and vibration-free designs for 24/7 industrial environments.

Leader Machine Tools machines are engineered to achieve fine finishing, uniform tolerances, and smooth profiles across the entire roll length.

Yes, fully automated CNC roll turning and roll grooving options are available for high-precision industries like paper mills and laminating plants.

Power depends on roll size and bed length, but most models operate efficiently on 7.5 HP to 30 HP motors.

Yes, our engineers handle installation, alignment, and operator training at your facility.

Copyright © 2025 Leader Machine Tools | All Rights Reserved.