CNC Lathe Machine

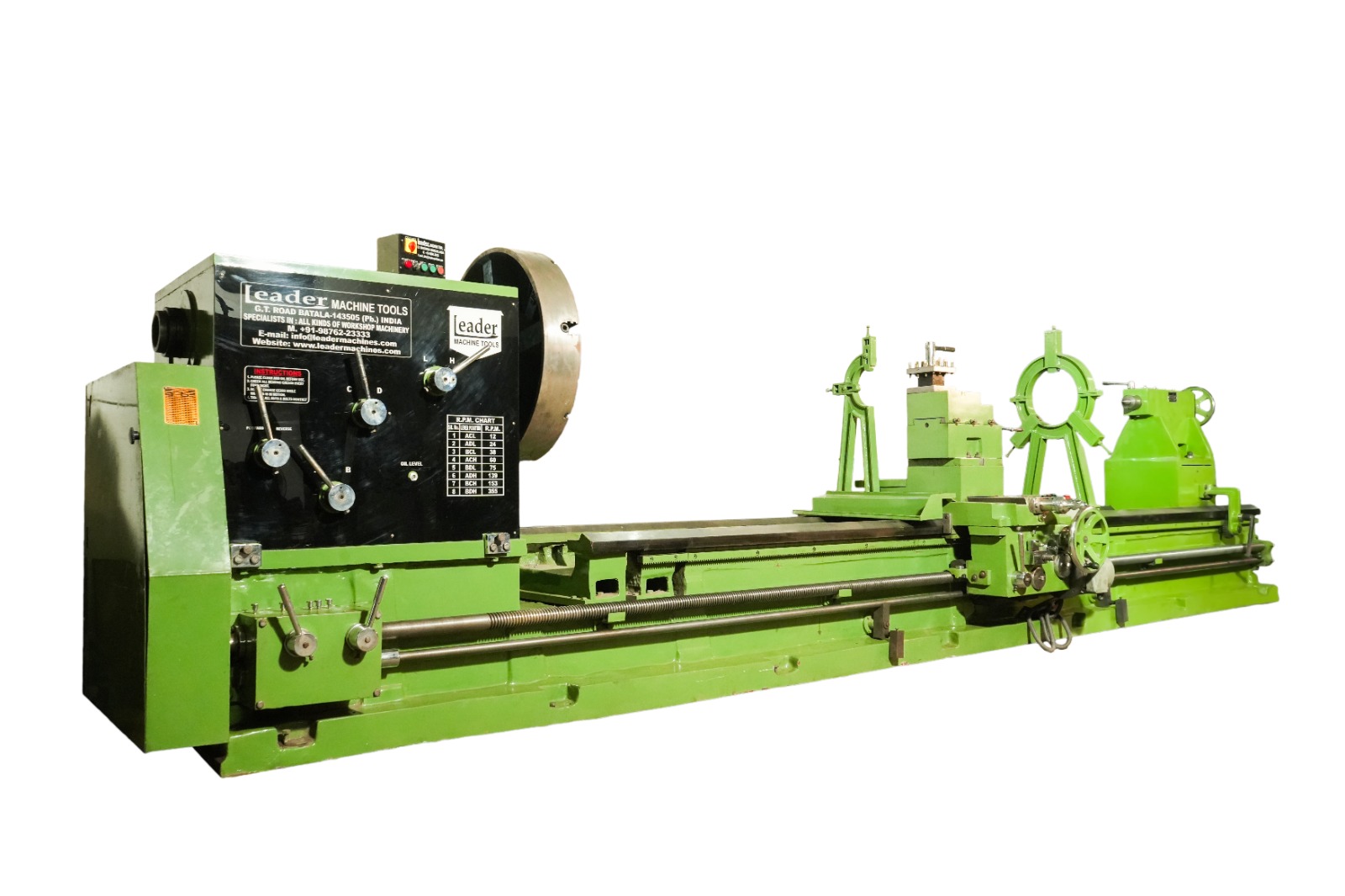

CNC Lathe Machine Manufacturer in Panipat – Leader Machine Tools (Since 1971)

A cnc lathe machine in Panipat is a metal-cutting tool used to rotate a workpiece and remove material with precision.

It performs turning, facing, threading, drilling, boring, and taper operations — essential for any metalworking, fabrication, or maintenance workshop.

Leader Machine Tools designs lathes for both manual and automated CNC operations in Panipat, offering models that meet small-shop and industrial production needs.

What Is a CNC Lathe Machine

A CNC Lathe Machine rotates the workpiece and uses programmed tool movement to perform turning, facing, threading, grooving, drilling, and taper cutting.

The machine runs on G-code and delivers precise machining with minimal manual handling.

It is ideal for mass production, repeat jobs, and high-accuracy parts.

Our CNC Lathe Machine Range

We manufacture CNC lathes for light, medium, and heavy machining. Each model supports custom spindle bore, bed size, tool post, controller, and motor power.

CNC Lathe Machine

For medium-scale production units and tool rooms.

◉ Stable accuracy

◉ Servo feed system

◉ High spindle speed

◉ Compact footprint

CNC Roll Lathe Machine

For roll turning in steel, paper, rubber, and textile plants.

◉ Heavy-duty bed

◉ High torque

◉ Suitable for long rolls

CNC Big Bore Lathe Machine

For large-diameter pipes and oil tools.

◉ Large spindle bore

◉ Strong headstock

◉ Low-RPM stability

CNC Oil Country Lathe Machine

For drill pipes, casing, and tubular tools.

◉ Large bore options

◉ Rugged construction

◉ Precision threading

Industries Using Our CNC Lathe Machines

CNC lathe machines are utilized across various industries due to their versatility and precision:

Automotive Industry

Manufacturing engine components, shafts, and other intricate parts.

Aerospace Sector

Crafting high-precision components such as turbine blades and structural elements.

Medical Field

Producing surgical instruments and orthopedic implants with exacting standards.

Oil and Gas Industry

Machining pipes, fittings, and other critical components.

General Manufacturing

Creating custom parts for machinery and equipment.

Major Components of CNC Lathe Machines

Understanding the key parts of a CNC lathe machine is essential for optimal operation:

| MODEL | SIZE | LMT-CNCL-2750X15 | LMT-CNCL-3250X20 | LMT-CNCL-3750X3000 | LMT-CNCL-4500X4000 | LMT-CNCL-6000X5000 | LMT-CNCL-7500X6000 | LMT-CNCL-10000X8000 | LMT-CNCL-12000X10000 |

| BED | |||||||||

| BED TYPE | TYPE | PEDESTAL | PEDESTAL | PLANER | PLANER | PLANER | PLANER | PLANER | PLANER |

| BED WIDTH | MM | 275 MM | 325 MM | 375 MM | 450 MM | 600 MM | 750 MM | 1000 MM | 1200 MM |

| BED GUIDEWAYS | GUIDE | HARDENED AND GROUND | |||||||

| CAPACITY | |||||||||

| SWING OVER BED | MM | 200 MM | 300 MM | 400 MM | 600 MM | 800 MM | 1000 MM | 1400 MM | 1800 MM |

| SWING OVER CROSS SLIDE | MM | 150 MM | 150 MM | 250 MM | 350 MM | 600 MM | 800 MM | 1000 MM | 1400 MM |

| ADMIT BETWEEN CENTER | MM | 300 / 600 / 900 | 1000 / 1500 | 2000 / 2500 | 3000 / 4000 | 5000 / 6000 | 7000 / 8000 | 9000 / 10000 | 12000 / 15000 |

| SPINDLE | |||||||||

| SPINDLE NOSE | NOSE | A2-5 | A2-6 | A2-8 | A2-8 | A2-11 | A2-15 | A2-15 | A2-15 |

| SPINDLE HOLLOW | MM | 52 | 65 | 80 | 80 | 100 | 120 | 180 | 180 |

| SPINDLE SPEEDS | RPM | 1500 | 1200 | 1000 | 800 | 600 | 300 | 300 | 300 |

| STANDARD POWER CHUCK | MM | 200 (3J) | 250 (3J) | 315 (3J) | 315 (3J) | 400 (3J) | 630 (3J) | 800 (3J) | 800 (3J) |

| AXIS | |||||||||

| X-AXIS STROKE | MM | 100 | 150 | 200 | 300 | 400 | 560 | 700 | 800 |

| X-AXIS RAPID | M/MIN | 8 | 8 | 8 | 8 | 8 | 6 | 4 | 4 |

| Z-AXIS STROKE | MM | 500 | 750 | 900 | 1100 | 1300 | 1500 | 2000 | 2500 |

| Z-AXIS RAPID | M/MIN | 8 | 8 | 6 | 6 | 5 | 5 | 4 | 4 |

| TOOLING | |||||||||

| TURRET MAKE | MAKE | PRAGATI | |||||||

| NUMBER OF STATION | NO | 4 | 6 | 6 | 8 | 8 | 10 | 10 | 12 |

| MAX BORING BAR CAPACITY | MM | 32 | 32 | 40 | 40 | 50 | 50 | 50 | 50 |

| TURNING TOOL SIZE | MM | 25×25 | 25×25 | 25×25 | 25×25 | 32×32 | 32×32 | 32×32 | 32×32 |

| TAILSTOCK | |||||||||

| CENTER HEIGHT | MM | 235 | 280 | 320 | 380 | 450 | 600 | 800 | 1000 |

| QUIL TRAVEL | MM | 100 | 125 | 150 | 200 | 200 | 200 | 220 | 250 |

| TAILSTOCK QUIL DIAMETER | MM | 75 | 80 | 90 | 100 | 120 | 150 | 180 | 200 |

| TAILSTOCK TAPER | MT | MT-4 | MT-4 | MT-5 | MT-5 | MT-5 | MT-6 | MT-6 | MT-6 |

| MOTOR AND ELECTRICALS | |||||||||

| SPINDLE MOTOR | H.P | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 40 |

| CNC CONTROLLER | |||||||||

| CONTROLLER SYSTEM | MAKE | SIEMENS / FANUC / MITSUBISHI / DELTA | |||||||

| STANDARD ACCESSORIES | |||||||||

| STEADY REST & FOLLOW REST | |||||||||

| OPTIONAL ACCESSORIES | |||||||||

| 4-JAW DOG CHUCK / 3-JAW SELF CENTERING CHUCK | |||||||||

Features and Functions of CNC Lathe Machines

CNC lathe machines offer a range of features that enhance their functionality:

High Precision

Achieve tight tolerances and consistent quality.

Automation

Reduce manual intervention, increasing efficiency and reducing errors.

Versatility

Perform multiple operations such as turning, facing, threading, and drilling.

Programmability

Store and execute complex machining sequences, facilitating repeatability.

Safety Features

Incorporate emergency stop buttons, safety interlocks to ensure operator safety.

CNC Lathe Machine Specifications Guide (For Users Comparing Models)

| Key Parameters Explained | |

| Specification | Meaning |

| Bed Length | Total length available for machining. |

| Swing Over Bed | Maximum workpiece diameter that can rotate. |

| Center Height | Distance from spindle center to bed. |

| Admit Between Centers | Maximum workpiece length. |

| Spindle Bore | Hole size inside spindle for long bars/pipes. |

| Spindle Speed | RPM range for different materials. |

| Turret Type | Number of tools supported. |

| Motor Power | Determines cutting force and efficiency. |

Choosing the Right CNC Lathe Based on Workload

| Category | Bore | Turning Length | Use |

| Small Workshops | Up to 80 mm | Up to 600 mm | Small batch jobs |

| Medium Industries | 80–150 mm | Up to 1500 mm | Mixed job loads |

| Large Industrial Plants | 150–300 mm | 2000–6000 mm | Heavy and long components |

| Heavy Engineering & Roll Units | 300–650 mm | 20–60 feet (Bed) | Rolls, shafts, large pipes |

CNC Lathe Machine Price in Panipat

CNC lathe machine price depends on swing diameter, bed length, spindle bore, controller, and motor capacity.

Typical CNC Lathe Price Range:

◉ Standard CNC Lathe: ₹7 lakh to ₹12 lakh

◉ Heavy Duty CNC: ₹12 lakh to ₹25 lakh

◉ CNC Roll Turning Lathe: ₹25 lakh to ₹60 lakh

◉ CNC Big Bore Lathe: ₹20 lakh to ₹45 lakh

FAQs – CNC Lathe Machine Buyers Commonly Ask

Choose the model based on part size, material, and production load.

• For small batch jobs: Standard CNC Lathe

• For roll or shaft machining: CNC Roll Turning Lathe

• For oil pipes and tubular parts: CNC Oil Country Lathe

• For large diameters: CNC Big Bore Lathe

Share your job size and material. Our team recommends the exact model.

CNC lathe price starts from ₹7 lakh and goes up to ₹60 lakh based on:

• Bed length

• Swing diameter

• Spindle bore

• Controller type

• Turret/tooling

• Motor capacity

• Application (general machining vs roll turning)

Check these parameters:

• Swing over bed

• Admit between centers

• Spindle bore size

• RPM range

We offer:

• Fanuc

• Siemens

• LMT Industrial Controller

All controllers support G-code, tool offsets, threading cycles, and program storage.

Yes. We manufacture machines with:

• Custom bed length up to 60 feet

• Bore size up to 650 mm

• Custom turrets (4-tool, 8-tool, electric or hydraulic)

• Tailstock or steady-rest options

• Special fixtures for rolls, shafts, tubes

All machines come with a 1-year standard warranty, plus access to original spare parts and lifetime technical assistance through our support team.

Yes. We export to 57+ countries including Nepal, Sri Lanka, UAE, Kenya, Saudi Arabia, and Nigeria. Machines are packed with export-grade wooden crating and anti-rust coating for safe delivery.

Most CNC lathes run on 415V 3-Phase.

Small CNC models can run on 220V with minor electrical adjustments.

Yes. We provide:

• On-site installation

• Machine leveling

• CNC program training

• Safety and maintenance training

• Test run with customer material

Daily checks: coolant, lubrication, chip removal

Weekly checks: turret alignment, tool wear

Monthly checks: backlash, servo alignment, way lubrication system

Yearly service recommended for recalibration.

Yes. All our CNC lathes support machining of:

• Stainless steel

• Alloy steel

• Cast iron

• Copper

• Aluminum

• Mild steel

Choose the right tool carbide grade for best results.

Typical accuracy:

• Dimensional accuracy: ±0.01 mm

• Repeatability: ±0.005 mm

Accuracy varies with tool condition and job size.

Yes. We export to 57+ countries across Middle East, Africa, and South Asia.

Machines are packed with:

• Anti-rust coating

• Vacuum wrapping

• Export wooden crates

Yes. Machines can be supplied with:

• Chip conveyors

• Magnetic separators

• Coolant filtration systems

These reduce downtime and improve tool life.

You receive:

• Warranty card

• Calibration report

• Electrical diagram

• Operating manual

• CNC programming guide

• Packing list

• GST invoice / export invoice

Yes. We manufacture roll turning CNC lathes with:

• 20–60 ft bed options

• Bore up to 650 mm

• Load capacity up to several tons

Designed for paper, steel, and rubber roll machining.

All machines come with a 1-year standard warranty and lifetime technical support.

Yes. Our engineers study your:

• Job size

• Material

• Production volume

• Required tolerance

• Budget

Then we recommend the most cost-effective CNC model.

Copyright © 2025 Leader Machine Tools | All Rights Reserved.