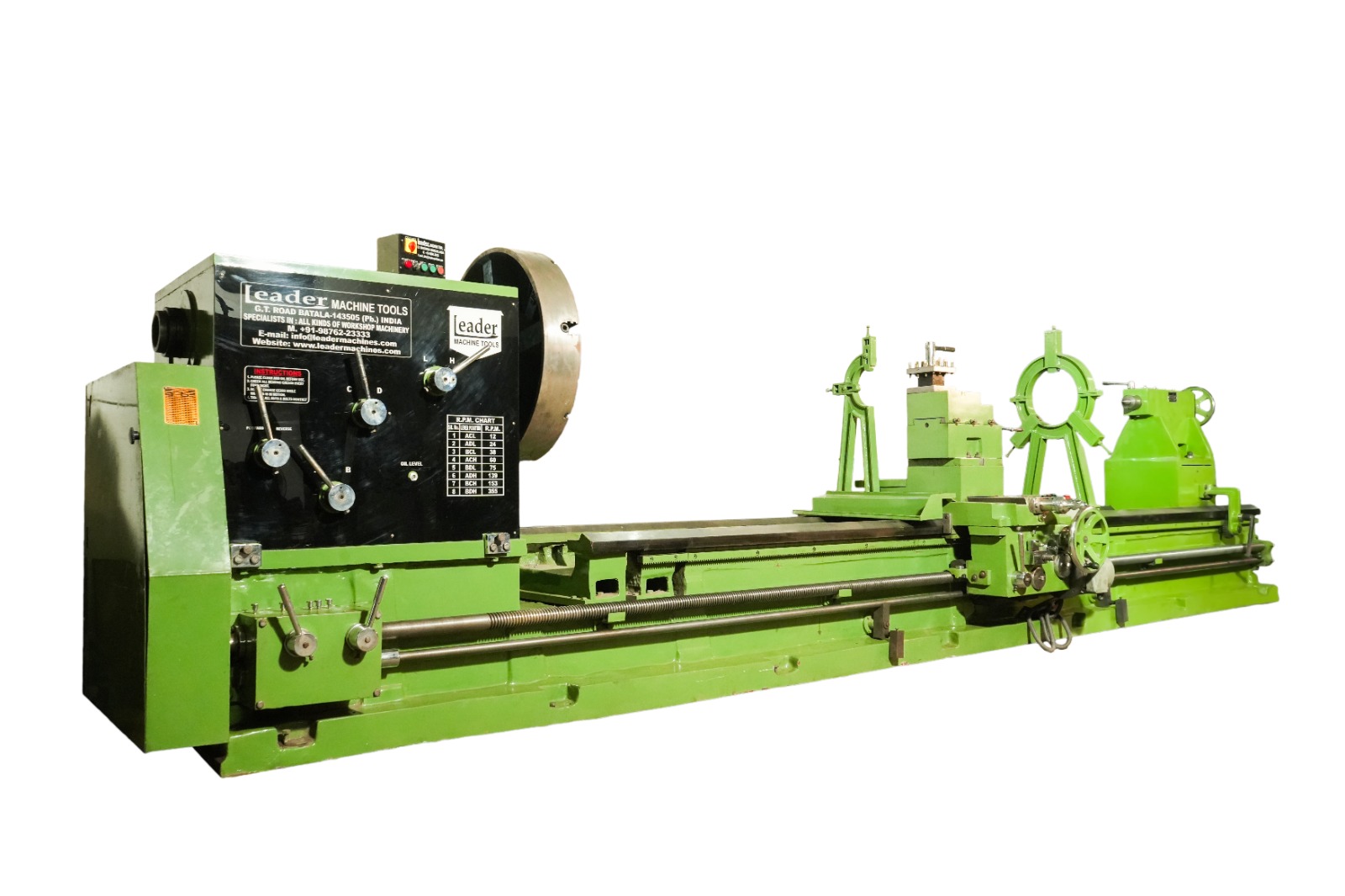

Roll Turning Lathe Machine

Roll Turning Lathe Machine Manufacturer in Nepal – Leader Machine Tools (Since 1971)

Leader Machine Tools manufactures high-precision roll turning lathe machines in Nepal for steel mills, paper mills, rubber plants, sugar units, and heavy engineering industries. Since 1971, we have supplied roll lathes in Nepal designed for heavy jobs, long shafts, and large-diameter rolls that need accurate machining.

Every machine is built in our ISO 9001:2015 certified facility with in-house casting, machining, and assembly. You get stable performance, high torque output, and long machine life.

What Is a Roll Turning Lathe Machine?

A roll turning lathe in Nepal is a heavy-duty machine designed to machine long rolls, shafts, pipes, and cylindrical components. It offers stable cutting performance during roughing and finishing, even on large-diameter jobs.

You use this machine for:

◉ Roll turning

◉ Roll grooving

◉ Roll machining

◉ Shaft machining

◉ Large-diameter turning

Industries include steel rolling mills, flour mills, paper mills, rubber plants, sugar mills, and heavy fabrication units.

Our Range of Roll Turning Lathe Machines

Leader Machine Tools offers a complete range engineered for different workloads and roll sizes.

Roll Lathe Machine

A general-purpose roll turning lathe for steel, paper, and rubber rolls.

◉ High torque headstock

◉ Heavy cast-iron bed

◉ Smooth feed and stable cutting

Roll Grooving Lathe Machine

Designed for grooving chilled rolls in flour mills and food-processing units.

◉ Extra heavy-duty bed

◉ Precision grooving system

◉ Hydraulic table feed

Rubber Roll Turning Lathe Machine

Used for machining rubber rolls for textile, laminating, and packaging industries.

◉ Smooth turning without burn marks

◉ Rigid base for vibration-free machining

Paper Roll Turning Lathe Machine

Used for paper mill rolls, suction rolls, and calendar rolls.

◉ Stable operation with long jobs

◉ Hardened bedways for accuracy

Sugar Roll Turning Lathe Machine

Built for sugar mill rollers and rough turning operations.

◉ High torque cutting

◉ Heavy-duty steady rests

Technical Specifications – Roll Turning Lathe Machine

| BELT DRIVE LATHE MACHINE – 16 FEET MODELS (PEDESTAL + TAPER PLANER) | |||

| Section | Parameter | Pedestal Type (16 FT) | Taper Planer Type (16 FT) |

| BED | Length of Bed | 16 FT | 16 FT |

| Width of Bed | 18" / 400 mm | 26" / 650 mm | |

| CAPACITY | Admit Between Centers | 136" / 3400 mm | 132" / 3350 mm |

| Swing Over Bed | 27" / 700 mm | 36" / 900 mm | |

| Swing Over Cross Slide | 21" / 525 mm | 26" / 650 mm | |

| Swing in Gap | 40" / 1000 mm | 48" / 1200 mm | |

| SPINDLE | Spindle Bore | 2" – 3" | 3" – 12" |

| Spindle Bore (mm) | 50 – 175 mm | 100 – 300 mm | |

| Spindle Speeds | 6 | 6 | |

| THREADING | Lead Screw Pitch | 2 TPI | 2 TPI |

| BSW Thread | 30 (8–28) | 31 (2–24) | |

| Metric Thread | 18 (1–7) | 31 (2–14) | |

| TAILSTOCK | Height of Center | 16" / 400 mm | 18" / 450 mm |

| Tailstock Quill Taper | MT-4 | MT-5 | |

| MOTOR REQUIRED | — | 5 HP | 7.5 HP |

| STANDARD ACCESSORIES | Steady Rest & Follower Rest | ||

| OPTIONAL ACCESSORIES |

4-Jaw Dog Chuck / 3-Jaw Self Centering Chuck / Taper Turning Attachment / Keyway Cutting Attachment / Tool Post Grinding Attachment / Main Motor / Electric Lamp / Quick Change Tool Holder |

||

Key Features of Leader Roll Turning Lathes

◉ Heavy cast-iron bed for stability

◉ High spindle torque for heavy cuts

◉ Smooth longitudinal and cross feed

◉ Hydraulic or mechanical table feed options

◉ Hardened bedways for long-term accuracy

◉ Supports rolls up to 20 tons (model dependent)

◉ Custom dimensions available

Applications of Roll Turning Lathe Machine

Our Roll Turning Lathe Machines are widely used across multiple industries due to their exceptional precision, durability, and efficiency. Key applications include:

Automotive Sector

Plays a crucial role in machining large components for heavy engineering and automobile.

Metal Industry

Used for machining large rolls in steel mills, aluminum plants, and rolling mills to ensure smooth finishing.

Textile Industry

Essential for shaping and maintaining textile rollers for continuous and smooth fabric processing.

Paper Industry

Ideal for processing paper mill rolls, ensuring high-quality output for paper manufacturing.

Plastic Industry

Used for manufacturing and refurbishing rubber and plastic rollers for industrial applications.

Why Choose Leader Machine Tools

◉ 50+ years of manufacturing experience

◉ ISO 9001:2015 certified process

◉ In-house casting and machining

◉ Export to 57+ countries

◉ Custom-built machines for heavy industries

◉ Reliable after-sales support and original spare parts

Roll Turning Lathe Machine Price

Roll turning lathe price depends on:

◉ Bed length | ◉ Swing diameter | ◉ Spindle bore size | ◉ Motor power | ◉ Hydraulic or mechanical feed | ◉ Custom features

Entry models start from ₹6,00,000, and large industrial models go up to ₹40,00,000+ depending on size.

FAQs – Roll Turning Lathe Machine

Choose size based on roll length and diameter. Small mills use 10–20 ft beds. Steel and paper mills often need 30–60 ft machines. Very large units require 60+ ft beds with 300–650 mm bores.

Prices start from ₹6 lakh for basic models and go up to ₹40–50+ lakh for extra heavy duty or CNC roll lathes. Price depends on bed length, bore size, spindle speed, and motor power.

Yes. You can customize bed length up to 75 ft and spindle bore up to 500 mm. We also build special machines for chilled rolls, sugar rolls, and rubber rolls.

Standard models are ready in 2–3 weeks. Large or custom machines in Nepal take 4–8 weeks depending on size and configuration.

A 20 ft machine needs around 5×2.5 meters. A 40–60 ft machine requires 10–14 meters of floor length. Extra heavy models require reinforced flooring.

Yes. Our engineers handle complete installation, leveling, alignment, test cutting, and operator training in Nepal.

Most machines run on 3-phase 415V. Large or CNC roll lathes may need 30–60 HP motors, so proper wiring and load capacity are required.

Roll lathes have heavy frames, wide beds, higher torque, and large bores. They are built for long, heavy rolls used in mills, not for small workshop jobs.

Steel rolling mills, paper mills, sugar mills, rubber and textile units, and heavy engineering plants in Nepal.

Yes. We stock chucks, steady rests, bearings, gears, lead screws, tool posts, and all major spares for every model in Nepal.

Both. Manual and CNC roll lathes support turning, roughing, finishing, and groove cutting. Special grooving attachments are available.

Models support 2–20 tons depending on bed size and center height.

Accuracy depends on model, but typical results include ±0.02 mm for CNC and ±0.05–0.1 mm for manual heavy duty machines.

Yes. We export to 57+ countries with export-grade wooden packing, rust protection, and container loading support.

Copyright © 2025 Leader Machine Tools | All Rights Reserved.