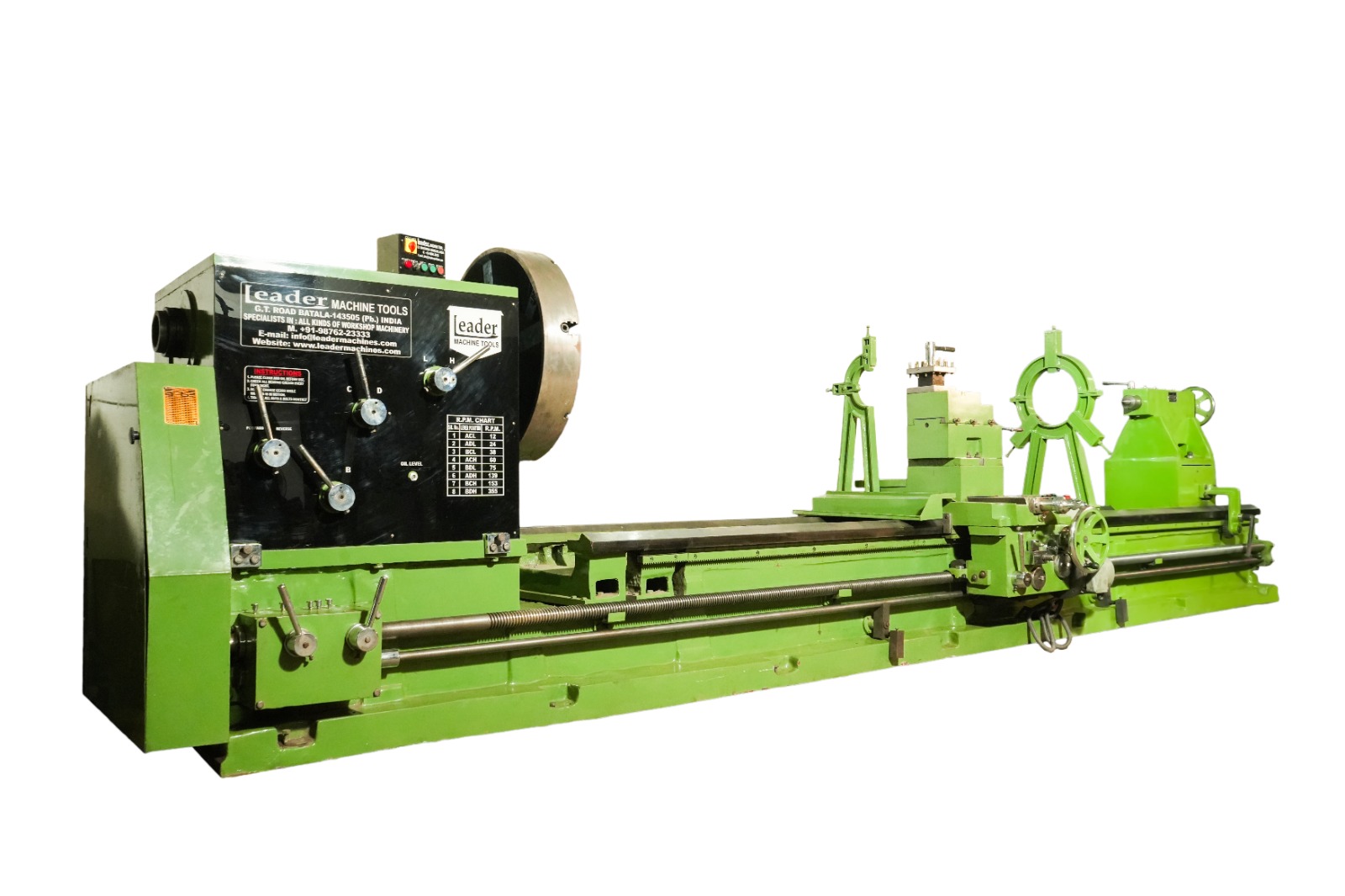

Roll Lathe Machine

Roll Lathe Machine Manufacturer in Nagpur

Leader Machine Tools is a trusted Roll Lathe Machine Manufacturer in Nagpur, known for delivering precision-engineered solutions to industries requiring heavy-duty machining. Our roll lathe machines in Nagpur are designed for superior performance, durability, and accuracy, ensuring seamless operation in roll turning applications.

Leader Machine Tools is a trusted Roll Lathe Machine Manufacturer in Nagpur, known for delivering precision-engineered solutions to industries requiring heavy-duty machining. Our roll lathe machines in Nagpur are designed for superior performance, durability, and accuracy, ensuring seamless operation in roll turning applications.

Related Search Keywords

Technical Specifications

| BELT DRIVE LATHE MACHINE – 16 FEET MODELS (PEDESTAL + TAPER PLANER) | |||

| Section | Parameter | Pedestal Type (16 FT) | Taper Planer Type (16 FT) |

| BED | Length of Bed | 16 FT | 16 FT |

| Width of Bed | 18" / 400 mm | 26" / 650 mm | |

| CAPACITY | Admit Between Centers | 136" / 3400 mm | 132" / 3350 mm |

| Swing Over Bed | 27" / 700 mm | 36" / 900 mm | |

| Swing Over Cross Slide | 21" / 525 mm | 26" / 650 mm | |

| Swing in Gap | 40" / 1000 mm | 48" / 1200 mm | |

| SPINDLE | Spindle Bore | 2" – 3" | 3" – 12" |

| Spindle Bore (mm) | 50 – 175 mm | 100 – 300 mm | |

| Spindle Speeds | 6 | 6 | |

| THREADING | Lead Screw Pitch | 2 TPI | 2 TPI |

| BSW Thread | 30 (8–28) | 31 (2–24) | |

| Metric Thread | 18 (1–7) | 31 (2–14) | |

| TAILSTOCK | Height of Center | 16" / 400 mm | 18" / 450 mm |

| Tailstock Quill Taper | MT-4 | MT-5 | |

| MOTOR REQUIRED | — | 5 HP | 7.5 HP |

| STANDARD ACCESSORIES | Steady Rest & Follower Rest | ||

| OPTIONAL ACCESSORIES |

4-Jaw Dog Chuck / 3-Jaw Self Centering Chuck / Taper Turning Attachment / Keyway Cutting Attachment / Tool Post Grinding Attachment / Main Motor / Electric Lamp / Quick Change Tool Holder |

||

Features of Roll Lathe Machine

High Precision & Sturdy Construction

Leader Machine Tools manufactures roll lathe machines with a rigid bed structure and high-grade cast iron components, ensuring superior stability and vibration resistance. This enhances machining accuracy while extending the machine’s lifespan.

High Precision & Sturdy Construction

Leader Machine Tools manufactures roll lathe machines with a rigid bed structure and high-grade cast iron components, ensuring superior stability and vibration resistance. This enhances machining accuracy while extending the machine’s lifespan. Heavy-Duty Performance

Designed for industrial-scale roll turning, our lathe machines handle large-diameter and heavy rolls with ease. The powerful spindle and precision feed mechanism provide smooth operation, making them ideal for steel, paper, and textile industries.

Heavy-Duty Performance

Designed for industrial-scale roll turning, our lathe machines handle large-diameter and heavy rolls with ease. The powerful spindle and precision feed mechanism provide smooth operation, making them ideal for steel, paper, and textile industries. Advanced Control System

Equipped with manual, semi-automatic, and CNC control options, our roll lathe machines offer user-friendly operation, precision cutting, and automated efficiency. These features help optimize productivity while minimizing manual effort.

Advanced Control System

Equipped with manual, semi-automatic, and CNC control options, our roll lathe machines offer user-friendly operation, precision cutting, and automated efficiency. These features help optimize productivity while minimizing manual effort. Versatile Machining Capabilities

Our machines support multiple machining operations, including turning, grooving, knurling, and threading. With adjustable feed rates and cutting speeds, they deliver consistent results across different materials.

Versatile Machining Capabilities

Our machines support multiple machining operations, including turning, grooving, knurling, and threading. With adjustable feed rates and cutting speeds, they deliver consistent results across different materials. Energy Efficient & Low Maintenance

Built with energy-efficient motors and wear-resistant components, our roll lathe machines consume less power while offering high output. They require minimal maintenance, reducing downtime and operational costs.

Energy Efficient & Low Maintenance

Built with energy-efficient motors and wear-resistant components, our roll lathe machines consume less power while offering high output. They require minimal maintenance, reducing downtime and operational costs.

Applications of Roll Lathe Machine

Roll lathe machines are widely used in multiple industries for precision roll turning and machining. Some of their key applications include:

Paper Industry

Essential for manufacturing and reconditioning paper mill rolls to ensure smooth production.

Steel & Metal Industries

Used for machining steel rolls, aluminum rolls, and copper rolls for rolling mills.

Textile Industry

Helps in machining rolls used in textile processing and fabric printing.

Rubber & Plastic Industries

Used for shaping rubber and plastic rolls required in industrial applications.

Heavy Engineering

Plays a crucial role in machining large cylindrical parts used in ship and heavy machinery construction.

Why Choose Leaders Machine Tools?

At Leader Machine Tools, we are committed to delivering top-notch Roll Lathe Machines that meet industry demands with exceptional performance and durability. Here’s why we are the preferred choice:

-

Decades of Expertise

Decades of ExpertiseWith years of experience, we have built a reputation for manufacturing high-quality roll lathe machines that exceed industry standards.

-

Superior Quality Assurance

Superior Quality AssuranceEvery machine undergoes rigorous quality checks to ensure precision, durability, and efficiency before reaching our customers.

-

Customization & Innovation

Customization & InnovationWe offer customized solutions tailored to specific industry needs, integrating the latest technology for enhanced automation and accuracy.

-

Customer-Centric Approach

Customer-Centric ApproachOur commitment to customer satisfaction drives us to deliver exceptional service, technical support, and prompt assistance whenever required.

FAQs – Roll Lathe Machine

A roll lathe machine is designed for turning, grooving, and finishing large industrial rolls used in steel, paper, rubber, sugar, and printing industries.

Unlike standard lathes, roll lathes feature heavier beds, higher torque, and longer centers to handle oversized rolls with precision.

We manufacture roll lathes in multiple bed lengths and swing capacities, suitable for small rubber rollers to large industrial steel rolls.

Yes. Machines can be supplied with crowning attachments, grooving tools, and custom tool-post setups depending on application.

Absolutely. The machines are built on heavy-duty castings with hardened guideways, ensuring stable machining during continuous operation.

Yes. We offer custom spindle bores, roll supports, fixtures, and bed lengths tailored to your exact roll dimensions.

Our machines deliver high dimensional accuracy using precision ground lead screws, rigid bedways, and vibration-free operation.

Copyright © 2025 Leader Machine Tools | All Rights Reserved.