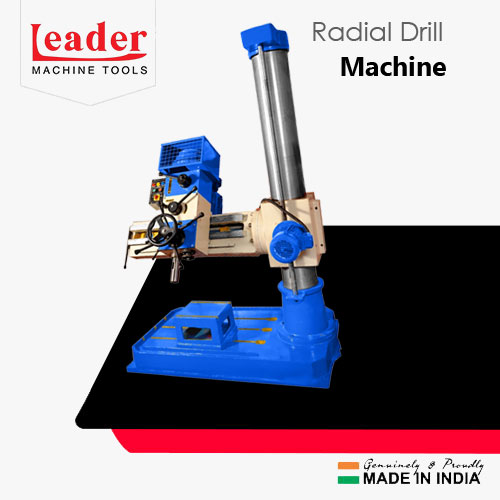

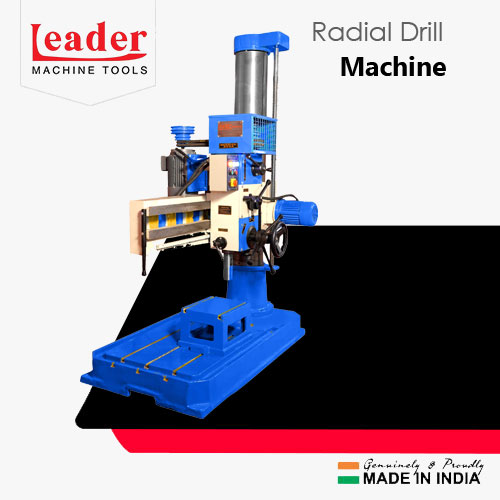

Radial Drill Machine

Radial Drill Machine Manufacturer in Ahmednagar – Leader Machine Tools (Since 1971)

Leader Machine Tools is one of India’s most trusted manufacturers and exporters of high-precision Radial Drill Machines in Ahmednagar, delivering engineering accuracy since 1971. Designed for power, rigidity, and long-term performance, our machines are built in our ISO 9001:2015 certified facility with strict quality control and premium-grade castings.

Whether you need a compact drilling solution for a workshop or a heavy-duty radial drill in Ahmednagar for industrial production, our machines ensure smooth drilling, tapping, boring, reaming, and counter-boring with zero vibration and maximum stability. Trusted across railways, fabrication units, steel plants, automotive workshops, and engineering industries in 57+ countries.

What Is a Radial Drill Machine?

A radial drill machine is a heavy-duty drilling tool where the arm rotates around the column, allowing the spindle to move horizontally and vertically. This flexible design enables drilling of large workpieces that cannot be moved easily.

Leader Machine Tools designs radial drills for precision, effortless operation, high torque output, and durability, suitable for both small shops and large industrial units.

Technical Specifications – Radial Drill Machine

- Semi-Geared Radial Drill Machine

- All Geared Radial Drill Machine

| MODEL | SIZE | LMT-ARDM-25-M | LMT-ARDM-32-M | LMT-ARDM-40-M | LMT-SRDM-40-AF | LMT-SRDM-50-AF |

| CAPACITY | DRILL IN C.I | 25 MM | 32 MM | 40 MM | 40 MM | 50 MM |

| DRILL IN M.S | 20 MM | 25 MM | 36 MM | 36 MM | 40 MM | |

| COLUMN | COLUMN DIAMETER | 127 MM | 152 MM | 180 MM | 220 MM | 240 MM |

| SPEED AND FEED | TAPPER IN SPINDLE | MT-4 | MT-4 | MT-4 | MT-4 | MT-4 |

| NUMBER OF SPEEDS | 6 | 6 | 6 | 6 | 6 | |

| RANGE OF SPEEDS | 80 - 700 | 80 - 700 | 80 - 700 | 80 - 700 | 80 - 700 | |

| NUMBER OF FEEDS | N.A | N.A | N.A | 3 | 3 | |

| WORKING RANGE | MINIMUM DRILLING RADIUS | 250 MM | 300 MM | 300 MM | 495 MM | 570 MM |

| MAXIMUM DRILLING RADIUS | 500 MM | 700 MM | 800 MM | 1,200 MM | 1,200 MM | |

| MINIMUM DISTANCE BASE PLATE TO SPINDLE | 300 MM | 320 MM | 300 MM | 300 MM | 330 MM | |

| MAXIMUM DISTANCE BASE PLATE TO SPINDLE | 900 MM | 1,000 MM | 1,000 MM | 1,100 MM | 1,300 MM | |

| QUIL TRAVEL | 125 MM | 125 MM | 135 MM | 150 MM | 150 MM | |

| MOTOR AND ELECTRICALS | DRILLING HEAD MOTOR | 1 H.P | 1 H.P | 1 H.P | 2 H.P | 3 H.P |

| LIFTING MOTOR | N.A | N.A | N.A | 0.5 H.P | 0.5 H.P | |

| STANDARD ACCESSORIES | TABLE BOX | |||||

| MODEL | SIZE | LMT-ARDM-40 | LMT-ARDM-50 | LMT-SRDM-60H | LMT-SRDM-80H | LMT-SRDM-100H |

| CAPACITY | DRILL IN M.S | 40 MM | 50 MM | 60 MM | 80 MM | 100 MM |

| DRILL IN C.I | 40 MM | 50 MM | 60 MM | 80 MM | 100 MM | |

| COLUMN | COLUMN DIAMETER | 230 MM | 280 MM | 350 MM | 550 MM | 650 MM |

| SPEED AND FEED | TAPER IN SPINDLE | MT-4 | MT-5 | MT-5 | MT-6 | MT-6 |

| NUMBER OF SPEEDS | 12 | 12 | 16 | 16 | 16 | |

| RANGE OF SPEEDS | 75–1,220 | 24–1,280 | 25–2,000 | 16–1,250 | 8–1,000 | |

| NUMBER OF FEEDS | 3 | 3 | 16 | 16 | 16 | |

| RANGE OF FEEDS | 0.10 – 0.25 | 0.10 – 0.56 | 0.04–3.2 | 0.04 – 3.2 | 0.04 – 3.2 | |

| WORKING RANGE | MINIMUM DRILLING RADIUS | 300 MM | 360 MM | 350 MM | 500 MM | 570 MM |

| MAXIMUM DRILLING RADIUS | 1,100 MM | 1,600 MM | 1,300 MM | 2,500 MM | 3,000 MM | |

| MINIMUM DISTANCE BASE PLATE TO SPINDLE | 430 MM | 300 MM | 320 MM | 550 MM | 750 MM | |

| MAXIMUM DISTANCE BASE PLATE TO SPINDLE | 1,210 MM | 1,050 MM | 1,220 MM | 2,000 MM | 2,500 MM | |

| QUIL TRAVEL | 220 MM | 315 MM | 315 MM | 450 MM | 450 MM | |

| MOTOR AND ELECTRICALS | DRILLING HEAD MOTOR | 3 H.P | 5 H.P | 7.5 H.P | 10 H.P | 20 H.P |

| LIFTING MOTOR | 1.5 H.P | 2 H.P | 3 H.P | 3 H.P | 3 H.P | |

| CLAMPING | CLAMPING | CLAM | MECHANICAL | MECHANICAL | HYDRAULIC | HYDRAULIC |

| STANDARD ACCESSORIES | TABLE BOX | |||||

Applications of Radial Drill Machine

Radial drill machines are widely used across manufacturing, construction, and engineering industries due to their versatility and efficiency. These machines are essential for:

Automotive Industry

Ideal for precise drilling in engine parts and metal structures.

Heavy Machinery

Supports large-scale drilling operations for industrial equipment.

Metalworking Industries

Used for drilling holes in steel, iron, and other metals.

Shipbuilding

Employed in fabricating large metal components.

Construction & Fabrication

Helps in creating strong joints and support structures.

Why Choose Leader Machine Tools for Radial Drill Machines?

A radial drill is an investment that must deliver accuracy, power, and long-term reliability — and that is exactly where Leader Machine Tools stands apart.

◉ Proven Engineering Excellence – Since 1971, we manufacture radial drill machines known for stability, vibration-free cutting, and long service life.

◉ High-Strength Construction – Heavy-duty cast iron columns and arms ensure rigidity during deep-hole drilling.

◉ Precision Performance – Smooth spindle travel, accurate feed settings, and consistent drilling quality.

◉ Custom Options Available – Tailored spindle speeds, table sizes, motor capacity, and drilling depth.

◉ Energy-Efficient & Low Maintenance – Designed for continuous operation with minimal upkeep.

◉ Trusted After-Sales Support – Fast spares availability and expert technical assistance across India & 57+ countries.

FAQs – Radial Drill Machine Buyers Commonly Ask

Our machines come in multiple capacities, ranging from light-duty to heavy-duty models. The exact drilling capacity depends on spindle size, motor power, and column diameter.

They are widely used in fabrication units, heavy engineering, automotive, steel plants, tool rooms, and machinery repair workshops.

Yes, Leader Machine Tools offers fully customizable options including spindle speeds, arm length, motor HP, and table size.

Yes, we offer on-site installation assistance and basic operator training across India.

Absolutely. We stock all critical spares and provide quick support to minimize downtime.

Most models run on 3-phase industrial supply. Specifications differ by machine size and drilling capacity.

Yes, our radial drill machines can perform drilling, tapping, boring, counter-boring, and reaming with ease.

Copyright © 2025 Leader Machine Tools | All Rights Reserved.